How to specify a quality rooflight & why it matters

You take pride in your work, and rightfully so. That means you want every element to be right for your clients and that includes rooflights. Rooflights have had a mixed reputation over the years, mostly down to a few manufacturers who operate outside NARM’s standards.

Unpicking tricky marketing language and getting to the bottom of a product’s actual specification can be tough for even the most seasoned architect or designer, so we’ve compiled a quick checklist that will help you to ensure your specified standard or bespoke rooflight meets the same exemplary standards as the rest of your project.

- Laminated glass: “Toughened” glass sounds good, but it doesn’t offer the protection you need for your clients’ wellbeing. Always select a laminated inner pane to protect against glass falling into the room below in case of breakage. If the rooflight will be walked on, choose one specifically designed for this with a thicker laminated outer pane and a non-slip covering.

- Insulating upstands: The construction and insulation of the upstand is as important as the glazing when it comes to the Uw insulating values. Always buy the recommended insulated upstand from the manufacturer of the rooflight, otherwise you will risk condensation and poor thermal performance.

- Size matters: Rooflight manufacturers refer to three different sizes: External kerb measurements (how far the rooflight extends onto the roof), structural opening measurements (how big the hole in the roof needs to be) and clear internal measurements (the actual area of the glass that is visible to let in light). When comparing prices, you should always compare the clear internal measurement as this will determine the daylight the occupant gets when the rooflight is installed.

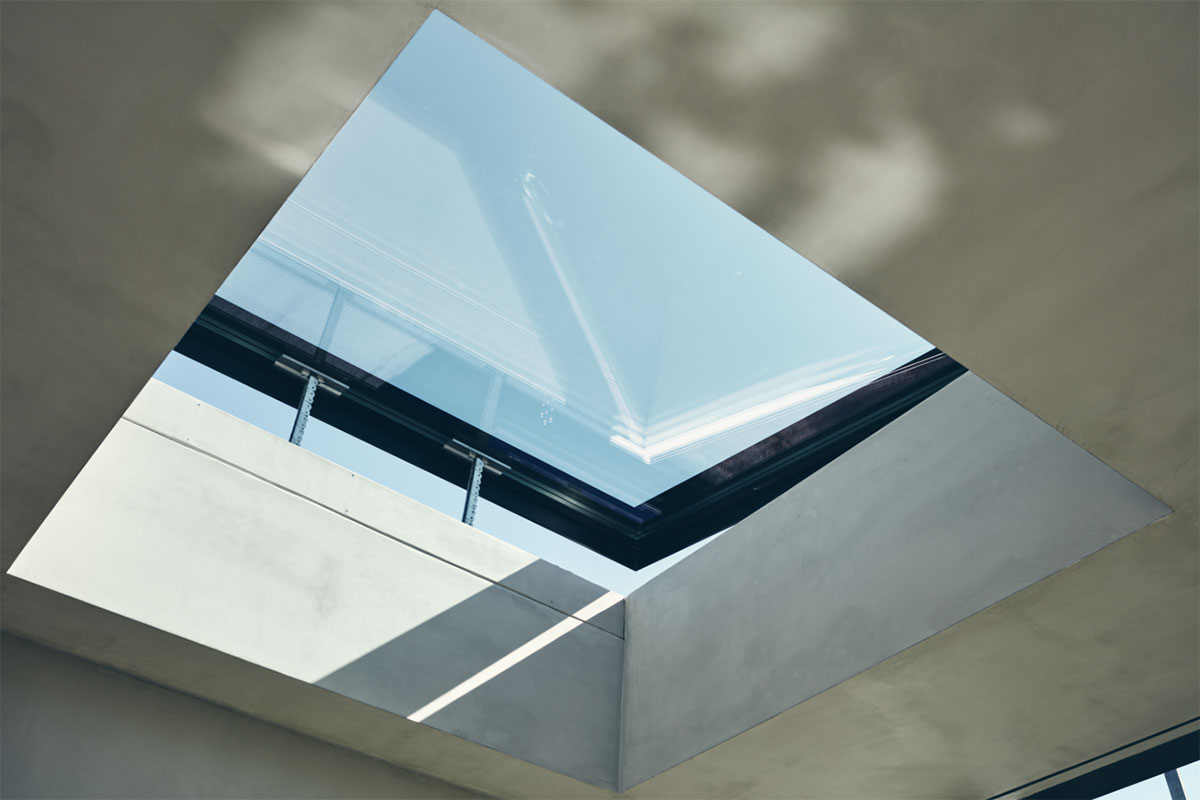

- Integrated actuators: Often you can choose an actuator that is integrated into the upstand, which is a nice feature as it creates additional robustness in the product and offers a very modern look from both the inside and the outside.

- Gaskets: Make sure that the upstand of the rooflight has a double gasket system to secure a tight seal against the weather.

- Frames: It is good practice to ensure that the aluminium frame that keeps the glazing in place is at least 5mm thick to make sure the frame lasts for many years.

- Pitch: To stop water pooling on a rooflight and to reduce dirt buildup, you’ll need to specify to the installer or contractor that your flat glass rooflights be installed at a pitch to aid water runoff and prevent water ingress. It is recommended to install all rooflights at a minimum pitch of 5 degrees.

- Security: Rooflights should be designed to resist criminal access attempts by having incorporated additional security features that have been proven to reduce crime.

- Installation: Some manufacturers offer supply and fit services, where a certified installer is responsible for the rooflight installation and weathering. This ensures that the installation is executed in accordance with manufacturer standards and fulfils the 10-year guarantee requirements, giving you peace of mind.

- Professional supporting tools: When specifying and working with rooflights, it is good practice for the manufacturer to share tools such as CAD/BIM objects and daylight applications to make it easier for you to incorporate daylight into your designs. It is also a must-have to provide well-documented installation guides and videos, so you can have peace of mind that the installation will go smoothly.

We welcome conversations with any architects, designers and contractors looking to specify rooflights as part of their designs. We can support you throughout the project, from deciding on the best configuration to meet your design objectives to decoding the specifications of the rooflights to align with regulatory and building standards requirements. Book a call and talk to one of our daylight experts today!